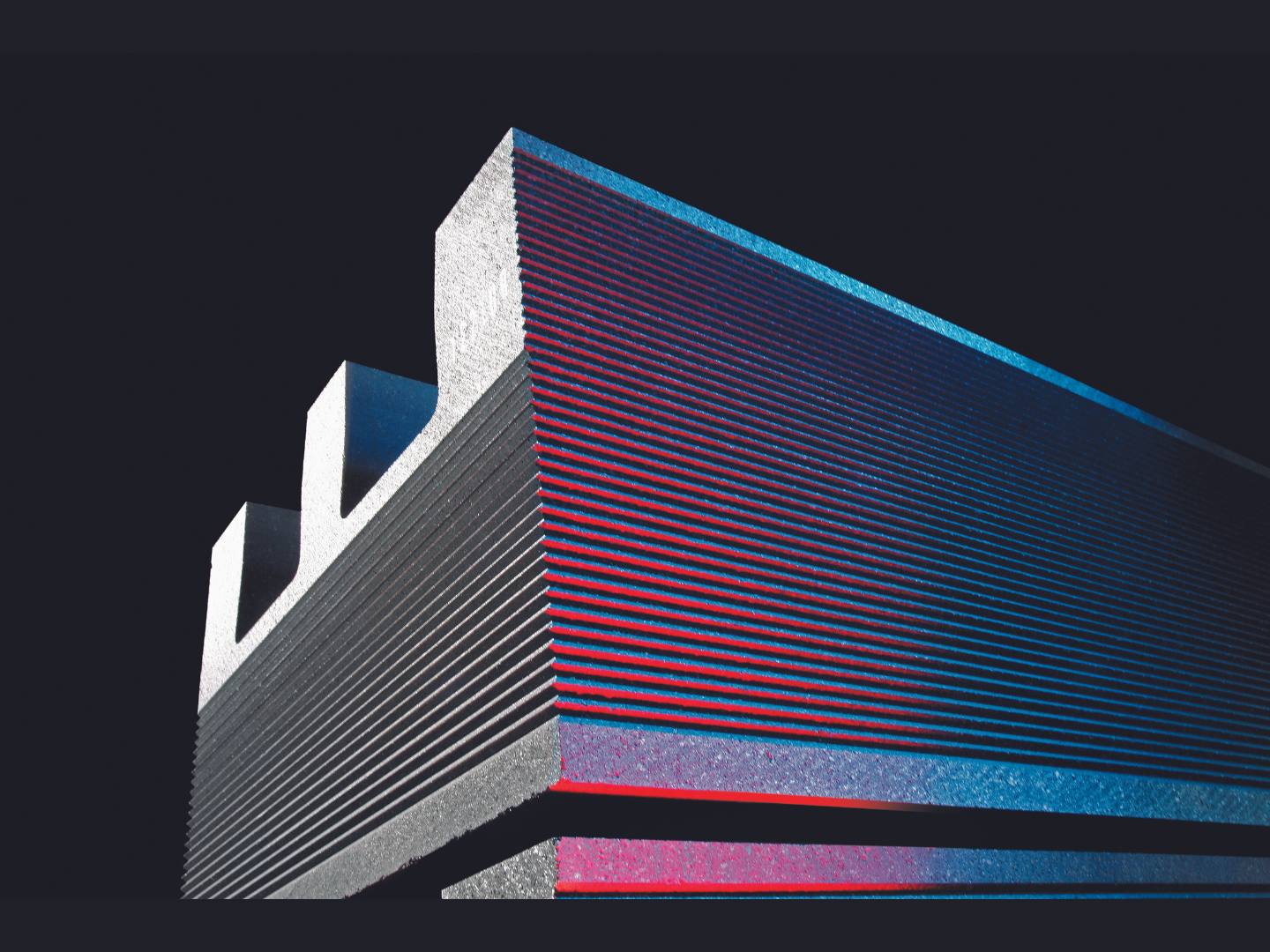

Cathode blocks are used in the lining of aluminum electrolysis cells. Sidewall blocks and ramming pastes round up the cathode product portfolio – providing complete custom-made solutions to optimally fit the requirements in the Aluminum Smelter.

We offer the complete product range from amorphous, graphitic, and graphitized cathodes. In addition, the Technical Service provides professional and highly qualified support around the application of cathodes, sidewalls, and ramming pastes in customers’ processes.

The continuous development of next generation products supports optimal solutions to the increasing challenges in the smelting process such as cell life, productivity, and energy efficiency.

We are the leading supplier of cathodes to aluminum producers.